Introduction

Screen printing is a versatile and popular method for transferring designs onto various surfaces, ranging from fabric and paper to wood and plastic. Its ability to reproduce intricate details and vibrant colors has made it a favored choice among artists, crafters, and commercial printers alike. In this comprehensive guide, we’ll delve into the essential materials needed for successful screen printing, as well as touch upon the intriguing topics of converting pictures to embroidery and machine embroidery designs.

Chapter 1: Fundamental Screen Printing Materials

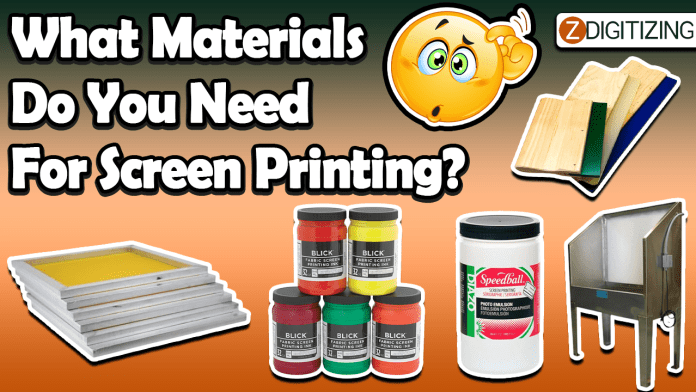

Before diving into the world of screen printing, it’s essential to gather the necessary materials to ensure smooth and efficient production. The primary items required include:

- Screen: The foundation of screen printing, screens are typically made from materials like silk, nylon, or polyester. The screen is stretched over a frame, creating a mesh surface that allows ink to pass through only in certain areas.

- Emulsion: This light-sensitive liquid is applied to the screen’s mesh. When exposed to light with a design or pattern blocking certain areas, the emulsion hardens and creates a stencil through which ink can pass.

- Squeegee: The squeegee is used to push ink through the stencil and onto the printing surface. It’s important to choose a squeegee with the appropriate hardness and size for your project.

- Ink: Screen printing inks come in various types, such as water-based, plastisol, and discharge inks. Select the ink that suits your project’s material and desired finish.

- Substrate: The surface onto which you’re printing, known as the substrate, can range from T-shirts and posters to ceramics and glass.

- Exposure Unit: This device exposes the emulsion-covered screen to UV light, helping create the stencil. A light source with consistent intensity is crucial for accurate and detailed designs.

- Drying and Curing Equipment: Once the ink is applied, it needs to dry and cure to ensure its longevity. This may involve heat curing using an oven or a heat press, depending on the type of ink used.

Chapter 2: The Process of Screen Printing

Understanding the process of screen printing is essential to appreciate the role of each material and how they come together to create stunning designs:

- Preparation: Start by cleaning and degreasing the screen to ensure the emulsion adheres properly. Once dry, apply the emulsion and let it dry in a dark environment.

- Design Exposure: Place the design or pattern on a transparent material, create a stencil by exposing the screen to light, and wash away the unexposed emulsion. This leaves behind a stencil with the desired design.

- Ink Application: Position the substrate under the screen and load ink onto one end of the screen. Use the squeegee to apply even pressure and move the ink across the stencil, transferring the design onto the substrate.

- Drying and Curing: Depending on the ink type, follow the appropriate drying and curing methods to set the ink onto the substrate. This ensures the design remains vibrant and durable.

Chapter 3: Converting Pictures to Embroidery Designs

While screen printing is a fascinating technique, the world of embroidery offers its own unique charm. Converting pictures into embroidery designs requires a different set of tools:

- Digital Design Software: Utilize design software like Adobe Illustrator, CorelDRAW, or specialized embroidery software to create or convert your images into digital embroidery files.

- Digitizing Software: For converting images to embroidery, you’ll need digitizing software like Wilcom or Hatch Embroidery. This software interprets the image and creates a stitch-by-stitch map for the embroidery machine to follow.

- Embroidery Machine: A computerized embroidery machine is essential for translating your digital embroidery file into a tactile design on fabric. These machines come in various sizes and capabilities, catering to different project requirements.

- Embroidery Threads: High-quality embroidery threads in a variety of colors are used to stitch the design onto the fabric. Choose threads that complement your design and fabric.

- Stabilizer: To prevent fabric distortion during embroidery, stabilizer is used. It’s placed underneath the fabric and provides support for the stitches.

Chapter 4: Machine Embroidery Process

Understanding the machine embroidery process is vital for achieving accurate and visually appealing results:

- Design Conversion: Begin by importing your image into digitizing software. Adjust settings like stitch density, underlay, and thread colors to match your vision.

- Digitization: This is the heart of the process. The digitizing software translates your image into machine-readable instructions, determining stitch types, directions, and densities.

- Stabilization: Hoop your fabric along with the appropriate stabilizer to keep it taut and stable during embroidery.

- Embroidery Setup: Load the digital embroidery file into your embroidery machine and thread it with the chosen colors.

- Embroidery: Let the machine work its magic as it meticulously follows the stitch map, creating your design with precision and detail.

- Finishing Touches: After embroidery is complete, trim any excess threads, remove the stabilizer, and give your project a final press to ensure it looks its best.

Conclusion

Both screen printing and machine embroidery offer captivating ways to bring your designs to life. While screen printing relies on stencils and ink to transfer designs, machine embroidery designs into intricate stitch patterns. By understanding the materials needed and the processes involved, you can embark on your creative journey with confidence, whether you’re printing bold designs on T-shirts or transforming images into textured embroidery artwork. So, gather your materials, unleash your creativity, and explore the endless possibilities these techniques have to offer.