Introduction

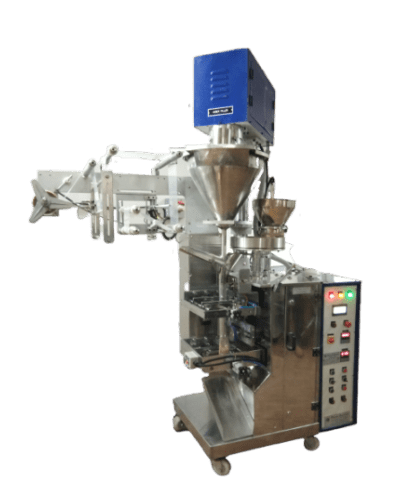

In the realm of modern manufacturing, where efficiency and precision are paramount, packaging technology has taken center stage. The Vertical Form Fill Seal (VFFS) machine stands as a pinnacle of packaging innovation, revolutionizing the way products are packaged into bags or pouches. This versatile and efficient equipment has transformed packaging processes across industries, enhancing product quality, reducing labor costs, and ensuring consistent packaging. In this article, we delve into the features, benefits, and widespread applications of the VFFS machine.

The Evolution of Packaging with VFFS Technology

The packaging industry has witnessed remarkable transformations over the years. The introduction of the VFFS machine marked a significant leap forward in automating the packaging process. Unlike traditional manual or semi-automatic methods, the VFFS machine offers an integrated solution that forms, fills, and seals bags or pouches in a continuous and streamlined manner.

Components of the VFFS Machine

- Film Unwinding System: The machine is equipped with a film unwinding system that dispenses the packaging material, whether it’s a roll of plastic film or laminated material. The film is pulled downward and positioned to form the bag.

- Forming Collar: The forming collar shapes the film into a vertical tube, creating a channel through which the product will be dispensed into the bag.

- Product Dispensing System: The product dispensing system accurately measures and dispenses the desired quantity of product into the formed bags. This system can accommodate various products, such as solids, liquids, powders, and granules.

- Sealing Mechanism: The sealing mechanism ensures that the bag is securely sealed after the product is dispensed. Different sealing methods, such as heat sealing, ultrasonic sealing, or impulse sealing, are used based on the packaging material and product characteristics.

- Control Panel and HMI: The VFFS machine features a control panel and Human-Machine Interface (HMI) that allow operators to adjust and monitor various parameters, including bag length, filling speed, sealing temperature, and machine status.

Benefits of the VFFS Machine

- Increased Efficiency: The continuous and automated nature of the VFFS machine significantly boosts packaging efficiency, allowing manufacturers to meet high production demands with ease.

- Consistency and Accuracy: The machine ensures uniform bag sizes, filling volumes, and sealing, resulting in consistent product presentation and customer satisfaction.

- Reduced Labor Costs: Automating the packaging process reduces the need for manual labor, leading to cost savings and increased operational efficiency.

- Enhanced Product Integrity: The VFFS machine maintains product quality by sealing bags airtight, protecting the contents from contamination, moisture, and external factors.

- Versatility: The VFFS machine’s flexibility allows it to handle a wide range of products and bag sizes, making it suitable for various industries and applications.

Applications Across Industries

- Food Industry: The VFFS machine is widely used in the food industry for packaging snacks, cereals, candies, frozen foods, and more. Its ability to ensure product freshness and visual appeal makes it an essential asset in the culinary world.

- Pharmaceutical Industry: Pharmaceuticals, including tablets, capsules, and powders, require precise and hygienic packaging. The VFFS machine ensures accurate dosing and contamination-free sealing.

- Pet Food Industry: The versatility of the VFFS machine extends to packaging pet foods, offering manufacturers a reliable and efficient solution for filling bags of various sizes with kibble and treats.

- Chemical and Agricultural Sectors: Fertilizers, seeds, pesticides, and other agricultural products benefit from the VFFS machine’s accurate dispensing and secure sealing, maintaining the integrity of the contents.

- Non-Food Products: The VFFS machine’s adaptability allows it to package non-food products, such as detergents, hardware items, and personal care products, ensuring safe and convenient handling.

Future Innovations and Sustainability

As technology continues to advance, the VFFS machine is likely to incorporate more advanced features, including enhanced sensors for better bag positioning, predictive maintenance capabilities, and improved energy efficiency. Additionally, the focus on sustainability will lead to the development of eco-friendly packaging materials and reduced energy consumption in packaging machinery.

Conclusion

The Vertical Form Fill Seal (VFFS) machine has ushered in a new era of packaging efficiency and precision. Its ability to form, fill, and seal bags or pouches in a continuous and automated manner has transformed packaging processes across industries. As manufacturing continues to evolve, this technology will remain a cornerstone in achieving higher productivity, reduced operational costs, and sustainable packaging solutions that meet the demands of modern consumers and industries alike.