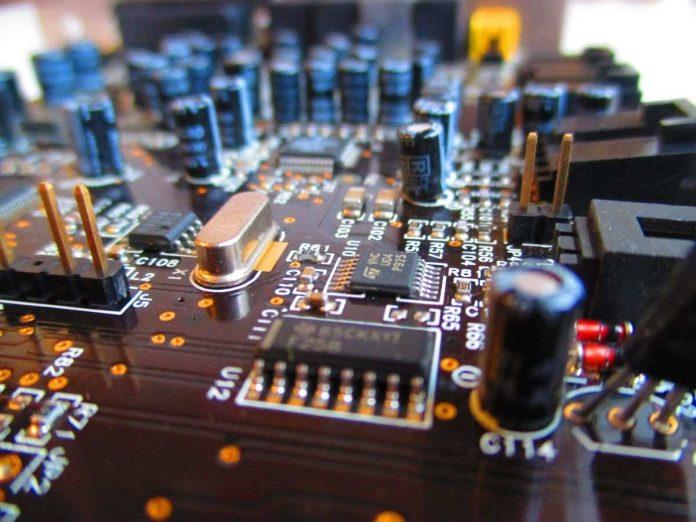

A metal core PCB is a circuit board which has a layer of copper on both sides. This allows it to be used as a heat sink, while also maintaining the strength of a traditional FR-4 circuit board. The metal core PCB is a type of laminate circuit board that is designed to conduct heat away from components such as resistors and capacitors. This makes it ideal for high-power circuits or other applications where heat needs to be dissipated quickly. MCPCBs are made using 2 layers of substrate material that have been laminated together with adhesive. One side of this material is coated with solder paste, while the other side is coated with nickel-plated copper foil. These two layers are then laminated together using an epoxy resin adhesive between them so that there is no exposed copper on either side of the board except for where it is needed for soldering components into place.

Metal Core Printed Circuit Board

MCPCBs are a relatively new type of circuit board that allows for higher signal transfer speeds and less interference than traditional fiberglass PCBs. They’re often used in high-frequency applications like RFID systems, GPS, and other wireless devices.

It is made from a standard FR4 substrate but has an additional layer of copper on one side and is laminated with a thin film of epoxy resin. This allows for multiple layers of signals to be printed onto the board and then connected together via vias (holes).

It is similar to fiberglass, but instead of using glass as the insulator, it uses thin sheets of copper foil laminated between two layers of epoxy resin. The main attraction here is that because there is no glass involved, it can handle much higher frequencies without requiring any special processing before use.

The main features of metal core PCB include:

High frequency: The dielectric constant of FR-4 board is about 4.6 while that of FR-5 board is about 5.6, so the impedance of the FR-5 board is much lower than that of FR-4, and it can be used to make high frequency circuit boards.

High density interconnect: The thickness of FR-5 board is only 0.2mm while that of the FR-4 board is 0.8mm, so the number of layers in FR-5 board is much more than that in FR-4 board.

Excellent thermal conductivity: The thermal conductivity of PTFE film has reached 1W/mK even without a heat sink, it can effectively reduce the temperature difference between the top and bottom surface during the operation process.

Low cost: Compared with other materials, aluminum alloy only needs to be coated with a thin layer (0.1mm), so it’s a very low cost compared with other materials.

Choosing a metal core printed circuit board company?

When you are choosing the metal core PCB providing company, there are a lot of things to consider. You need to make sure that the manufacturing company is reliable and has a good reputation in the industry. You also need to make sure that they have a good track record for delivering on time and within budget. You need to get in touch with 2-3 clients of the company and talk to them about the pros and cons of the company. The following are some of the things you need to think about when choosing a manufacturer:

- How long have they been in business?

- What kind of experience do they have?

- Do they have an ISO or any similar kind of certification?

- Do they provide free of cost samples?

- What is their customer service like?

- How advanced are their facility and equipment?

In addition to that, make sure the company offers great support.