Hydrocarbon extraction is a popular method for extracting essential oils and other compounds from plants. It is a process that requires careful understanding and adherence to safety measures to ensure the operator’s and the environment’s well-being. In this article, we will explore the different aspects of hydrocarbon extraction and provide a step-by-step guide on how to use a hydrocarbon extractor safely and effectively.

Understanding Hydrocarbon Extraction

What is Hydrocarbon Extraction?

Hydrocarbon extraction is a technique that uses hydrocarbon solvents, such as butane or propane, to dissolve plant material and extract desired compounds. This highly efficient method can extract compounds, including terpenes, cannabinoids, and essential oils.

When it comes to hydrocarbon extraction, the choice of solvent is crucial. Butane and propane are commonly used due to their low boiling points and excellent solvency properties. These solvents can effectively dissolve the desired compounds from the plant material, leaving behind impurities and unwanted substances. For further information about hydrocarbon extraction, feel free to visit HH Extraction.

Hydrocarbon extraction is widely used in various industries, including producing essential oils, pharmaceuticals, and cannabis concentrates. The process allows for extracting specific compounds, resulting in highly concentrated and potent products.

The Role of Hydrocarbon Extractors in the Process

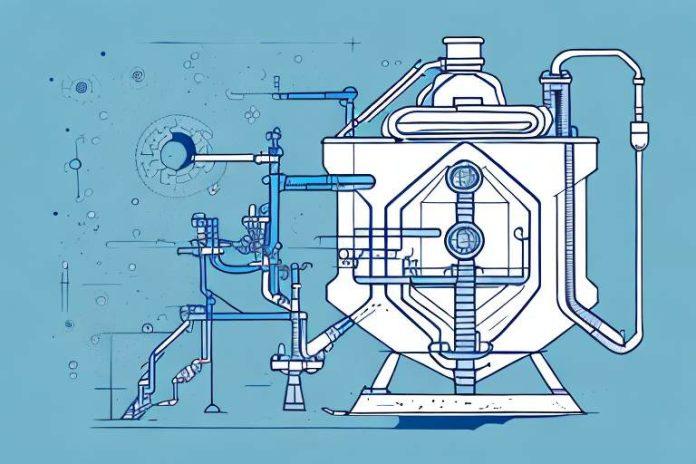

Hydrocarbon extractors play a crucial role in the extraction process. These specialized devices are designed to safely contain the solvent and plant material, allowing for efficient extraction and minimizing potential hazards. The extractor consists of several components: a collection chamber, solvent tank, and filtration system.

The collection chamber is where the plant material is placed for extraction. It is carefully designed to provide optimal conditions for the solvent to interact with the plant material, ensuring maximum extraction efficiency. The chamber often has various features, such as agitation mechanisms or temperature controls, to enhance the extraction process.

The solvent tank holds the hydrocarbon solvent, which is pumped into the collection chamber. The solvent is carefully selected to ensure compatibility with the desired compounds and the extraction equipment. Maintaining the right solvent-to-plant material ratio is crucial to achieving the desired concentration of the extracted compounds.

Once the extraction process is complete, the solvent and extracted compounds must be separated. This is where the filtration system comes into play. The system is designed to remove any remaining plant material, impurities, or unwanted substances from the extracted solution. This step ensures the purity and quality of the final product.

Hydrocarbon extractors are designed for efficiency, safety, and scalability. Depending on the desired production capacity, extractors can range from small-scale devices suitable for personal use to large-scale industrial systems capable of processing large quantities of plant material.

Overall, hydrocarbon extractors are essential tools in the hydrocarbon extraction process. They provide a controlled environment for efficient extraction, allowing for producing high-quality extracts used in various industries.

Essential Equipment for Hydrocarbon Extraction

The Hydrocarbon Extractor

The hydrocarbon extractor is the most critical equipment for hydrocarbon extraction. It is essential to choose a high-quality extractor specifically designed for this purpose. Look for durable construction, secure seals, and proper ventilation to ensure optimal performance and safety.

Safety Gear and Tools

When working with hydrocarbon solvents, it is crucial to prioritize safety. Always wear appropriate safety gear, including gloves, goggles, and a lab coat, to protect yourself from potential contact with the solvent. Additionally, ensure to have tools such as a fire extinguisher, a leak detector, and a well-ventilated workspace to handle emergencies.

Safety Measures in Hydrocarbon Extraction

Understanding the Risks

Before using a hydrocarbon extractor, it is essential to know the potential risks associated with the process. Hydrocarbon solvents are highly flammable and can pose a fire hazard if improperly handled. They can also be toxic if inhaled or ingested. Understanding these risks will help you take the necessary precautions to minimize them.

Safety Protocols to Follow

To ensure safe operation, it is crucial to establish and follow strict safety protocols. Start by creating a well-ventilated and designated extraction area away from ignition sources. Always handle hydrocarbon solvents in a well-ventilated and spark-free environment. Additionally, have an emergency plan and train all personnel on safety procedures and protocols.

Step-by-Step Guide to Using a Hydrocarbon Extractor

Preparing the Extractor

Before starting the extraction process, preparing the hydrocarbon extractor adequately is essential. Begin by ensuring that all seals and fittings are properly tightened to prevent any leaks. Double-check that the filtration system is clean and free from any debris. Lastly, ensure the empty collection chamber is ready to collect the extracted compounds.

Running the Extraction Process

Once the hydrocarbon extractor is prepared, it’s time to begin the extraction process. Start by loading the plant material into the collection chamber. Next, carefully open the solvent tank and fill it with the predetermined amount of hydrocarbon solvent. Close the solvent tank securely and initiate the extraction process according to the manufacturer’s instructions.

Post-Extraction Cleanup and Maintenance

After the extraction process is complete, proper cleanup and maintenance are crucial. Begin by carefully removing the extracted compounds from the collection chamber. Ensure that all residual solvent is purged or evaporated in a designated area. Thoroughly clean the hydrocarbon extractor, paying close attention to the seals and filtration system. Regular maintenance will help ensure the longevity and continued safety of the extractor.

Maximizing the Effectiveness of Your Hydrocarbon Extractor

Best Practices for Hydrocarbon Extraction

To maximize the effectiveness of your hydrocarbon extractor, it is essential to follow best practices. Start by choosing high-quality plant material with the desired profile of compounds. Properly grind or break down the material to increase its surface area and enhance extraction efficiency. Lastly, optimize extraction parameters, such as temperature and duration, based on the specific compounds you aim to extract.

Common Mistakes to Avoid

While using a hydrocarbon extractor, there are common mistakes that operators should avoid. One of the most critical mistakes is neglecting safety protocols, which can lead to accidents and injuries. Another mistake is overloading the extractor with excessive plant material, resulting in inefficient extraction and potential damage to the equipment. Lastly, using low-quality solvents can compromise the quality of the extracted compounds.

Using a hydrocarbon extractor safely and effectively requires proper understanding, equipment, and adherence to safety measures. By following the guidelines outlined in this article, you can harness the full potential of your hydrocarbon extractor while maintaining a safe working environment. Remember, safety should always be the top priority in any extraction process.