Developing a new electronics product requires the specialized skills of both printed circuit board (PCB) designers and hardware engineers. While they work closely together, pcb layout service are distinct disciplines. Understanding the key differences in their focus, tools, skills and design workflows is important for effective collaboration.

The Focused Role of PCB Design

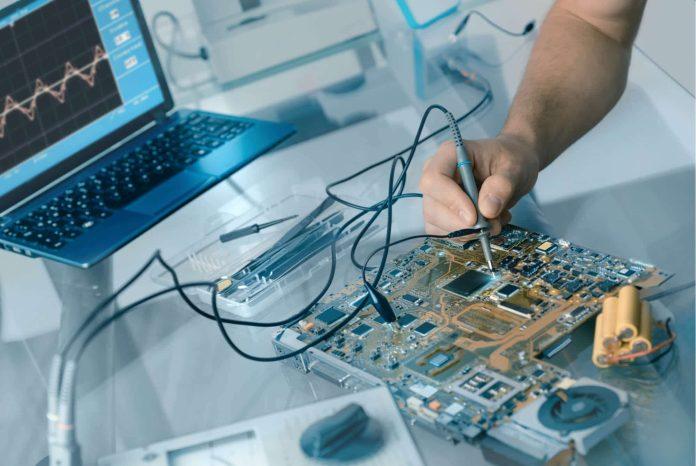

The PCB designer is responsible for laying out the printed circuit board that will physically support and connect electronic components. Their primary goal is to translate the schematic diagram into a board layout that can be manufactured.

Specific PCB design tasks include:

- Positioning components for optimal electronic performance, manufacturability, serviceability and cost

- Routing traces to make electrical connections between components

- Integrating vias and multiple layers to enable complex circuitry

- Incorporating appropriate design rules for manufacturability, reliability and safety

- Optimizing the board for thermal management, electromagnetic compatibility and signal integrity

To complete these tasks, PCB designers need specialized skills and knowledge. This includes expertise with PCB design software tools like Altium, KiCad or Eagle. An understanding of PCB materials, fabrication techniques, and design principles for high-speed or high-power circuits is also important.

The PCB designer must optimize the physical layout while adhering to constraints. This can involve complex spatial planning to fit many components and connections into a limited space. Trace widths, separations, and impedances need careful tuning. Thermal management presents both mechanical and electrical challenges. The PCB designer also needs to ensure manufacturability and testability.

The PCB designer’s role stays focused on the board layout rather than the overall product. Their goal is to effectively route connections between components predefined by hardware engineers.

The Broader Role of Hardware Design

While PCB design handles the layout of a single circuit board, hardware design encompasses the full electronics development process. Hardware engineers are responsible for:

- Defining the product requirements, specifications and use cases

- Developing the system architecture and partitioning major functional blocks

- Creating circuit schematics and performing circuit simulation

- Selecting electronic components and external interfaces

- Prototyping design concepts and testing performance

- Mechanical engineering tasks like enclosure design

Skills for effective hardware design include strong systems thinking, the ability to verify circuits through simulation and prototyping, and broad knowledge of electrical engineering principles.

Hardware design takes a big-picture view to transform product requirements into technical solutions. Determining the electronics architecture and functionality precedes the detailed PCB layout stage. This involves evaluating design tradeoffs to balance factors like performance, power, cost, manufacturability, and time-to-market.

A pcb layout engineer develops functional block and system specifications that the PCB designer will later implement. Defining interfaces between blocks is crucial to partitioning across multiple boards or ICs. The hardware team also selects major components that will need to be integrated into the PCB layout.

Key Differences in Focus

PCB design and hardware development differ significantly in their scope and concerns:

- Scope: PCB design focuses narrowly on layout of a single board, while hardware design covers the entire product development process.

- Tools Used: PCB designers spend most of their time in specialized CAD software while hardware engineers use system modeling, simulation and prototyping tools.

- Design Concerns: PCB designers are focused on physical layout constraints while hardware designers are concerned with overall product architecture and functionality.

- Skills Needed: Strong spatial skills are critical for PCB layout, while hardware design requires system-level thinking and a broad foundation in electrical engineering.

- Design Process: PCB designers cannot start their layout work until hardware architects have defined the high-level product specifications and schematics.

Achieving Effective Collaboration

Although PCB design and hardware development have distinct roles, close collaboration between the two disciplines is crucial for success.

Schematics, component specifications, design rules and other information must be continuously shared between hardware and PCB teams. Ongoing design reviews and feedback loops help keep the PCB layout aligned with overall product goals.

For example, hardware architects may need to adjust their system partitioning to simplify PCB routing. PCB designers can provide input on design-for-manufacturing issues that influence component selection and placement.

Smooth hand-offs between phases require excellent communication skills. PCB designers may collaborate with hardware team members to evaluate layout options. Interactive discussions lead to optimizing the design from both system and physical perspectives.

The end result should be a PCB layout that successfully realizes the hardware architecture defined by systems engineers. Careful coordination minimizes costly re-spins and delays.

Additional Considerations

- For very complex designs, hardware engineers may work with PCB designers during the schematic design phase to provide layout guidance and design rule development. Early PCB designer input can improve the feasibility of routing and optimization in high-density designs. In contrast, on simple, low-component-count boards, the lines between hardware design and PCB design may blur. For simple circuits, a single engineer may handle the entire process from architecture to layout.

- The rise of multi-board systems and modular electronics architectures provides more opportunities to divide work between hardware and PCB teams. Groups can focus on developing particular subsystems independently before integration.

- Manufacturing techniques like multi-chip modules (MCMs) are bringing PCB fabrication and IC fabrication closer together. This requires hardware and PCB designers to understand the processes and interface requirements for both domains.

- For maximum efficiency, hardware and PCB designers should utilize consistent design environments and workflow tools as much as possible. Shared data formats, version control, and design management tools help avoid errors and rework caused by tool mismatches.

- The details vary for different products and organizations, but the core difference remains: hardware engineers focus on architecture and functionality while PCB designers focus on physical implementation. Effective collaboration between these complementary roles leads to building great electronics products.

Conclusion

PCB designers and hardware engineers play complementary roles with unique priorities and required skillsets. PCB designers route connections between predefined components while hardware designers determine the product architecture and specifications.

Recognizing their distinct perspectives helps establish effective collaboration and division of responsibilities on electronics projects. With close coordination throughout the design technology in embedded system processes, PCB and hardware teams can combine their expertise to transform product concepts into optimized physical devices.