When it comes to creating a leak-free, secure seal in industrial applications, Flexitallic gaskets are the name that stands out. With a history dating back over a century and a reputation for excellence, these gaskets have become a staple in various industries worldwide. In this article, we will delve into the world of Flexitallic gaskets, exploring their features, applications, and why they are the go-to choice for sealing solutions.

The Legacy of Flexitallic

The story of Flexitallic began in 1912 when the company was founded in Newark, New Jersey. From its inception, Flexitallic focused on innovation in gasket technology. Their first breakthrough came in 1917 when they introduced the spiral-wound gasket, a design that remains a standard in the industry to this day. This commitment to innovation and quality has been a hallmark of the company’s success.

Unparalleled Material Selection

One of the key reasons Flexitallic gaskets have stood the test of time is their dedication to using high-quality materials. These gaskets are available in a wide range of materials, including:

Graphite: Ideal for high-temperature applications, graphite gaskets offer excellent thermal and chemical resistance.

PTFE (Polytetrafluoroethylene): Known for its exceptional chemical resistance, PTFE gaskets are commonly used in industries dealing with corrosive fluids.

Spiral Wound: These gaskets combine graphite or PTFE’s resilience with metal’s strength, making them suitable for high-pressure applications.

Ring Type Joints (RTJs): Typically used in high-pressure and high-temperature environments such as the oil and gas industry, RTJ gaskets are designed for precision and reliability.

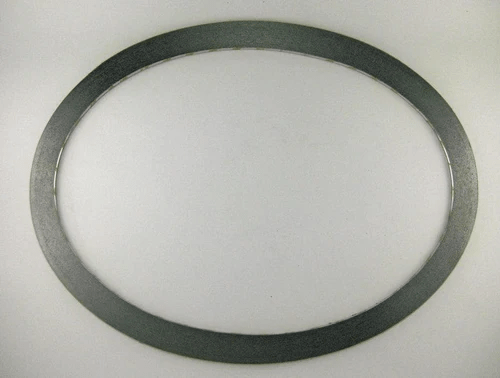

Kammprofile: Kammprofile gaskets provide a reliable seal with their serrated metal core, making them suitable for applications with fluctuating temperatures and pressures.

Non-Asbestos: These gaskets offer a safer alternative to asbestos, ensuring a reliable seal without health risks.

Versatile Applications

Flexitallic gaskets find applications in a diverse range of industries owing to their adaptability and reliability:

Oil and Gas: In the demanding environments of the oil and gas industry, Flexitallic gaskets provide leak-free sealing solutions for pipelines, wellheads, and valves.

Chemical Processing: The chemical industry relies on Flexitallic gaskets to seal reactors, pumps, and other equipment handling corrosive substances.

Power Generation: From traditional power plants to nuclear facilities, Flexitallic gaskets play a crucial role in maintaining the integrity of critical systems.

Pharmaceuticals: In pharmaceutical manufacturing, where sterility is paramount, these gaskets are used to ensure contamination-free processes.

Food and Beverage: Flexitallic gaskets meet the stringent requirements of the food and beverage industry, ensuring safe and sanitary sealing in processing equipment.

Aerospace: In the aerospace sector, where extreme conditions are the norm, these gaskets help seal vital aircraft and spacecraft components.

Innovative Solutions

Flexitallic doesn’t just produce gaskets; they offer innovative sealing solutions. For instance, their heat exchanger gasket is designed to reduce downtime during maintenance, providing a cost-effective and efficient solution for heat exchanger gasket replacement. This innovation illustrates their dedication to addressing industry challenges and improving efficiency.

The Sustainability Factor

In today’s world, sustainability is a key consideration. Flexitallic recognizes this and has taken steps to reduce its environmental impact. They offer a range of low-emission sealing solutions that help reduce fugitive emissions in industries where environmental stewardship is a priority. These gaskets maintain their exceptional sealing performance and contribute to a greener future.

Expert Support

Flexitallic’s commitment to excellence extends to its customer support. They provide technical expertise and support to ensure customers select the right gasket for their needs. They offer responsive assistance to customers worldwide with a global network of facilities and experts.

Conclusion

Flexitallic gaskets have earned their reputation as a reliable and innovative sealing solution provider. With a history of over a century, a dedication to quality materials, and a commitment to addressing industry challenges, Flexitallic remains a trusted choice in various sectors. Whether you are in the oil and gas, chemical, pharmaceutical, or any other industry requiring dependable sealing solutions, Flexitallic gaskets are a name you can rely on for leak-free, secure seals that stand the test of time.