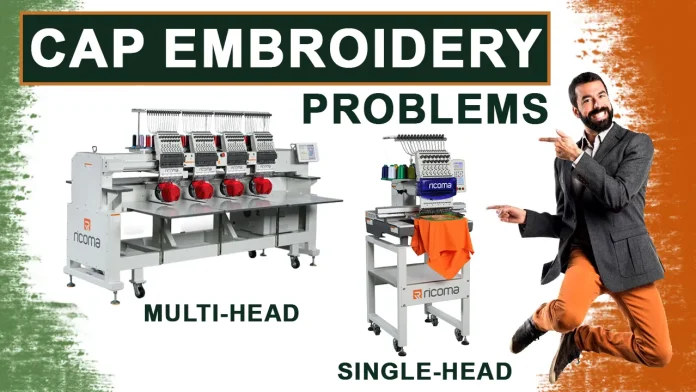

Headdresses are one the most extensively used particulars in the World. But we face cap embroidery problems day by day. In this composition, we will describe how to break cap embroidery problems with multi head and single head embroidery machine.

Preface

The custom chapeau embroidery has been enhanced with the moxie of the manufacturer and thus includes experience. Any error or cap embroidery problem in the custom vesture can spark a significant loss as you’ll give the client mitering with a minor quality job. For specific cap embroidery problems to be excluded, some typical digitalization issues of custom chapeau embroidery should be avoided to achieve the stylish quality embroidery headdresses of Embroidery digitizing.

generally, caps are the most grueling thing for embroidery. thus, specific pivotal questions should be treated cautiously inside the custom chapeau embroidery, whether the association is expanding.

Let’s bandy Some Common Cap Embroidery Problems

Embroidery Hooping Mistakes

To begin with, crimes are observed in artificial embroidery. But, the first- ever task to do now is to hold the fabric in the embroidery circle. You can show the point of circumstance where the cap embroidery problem happed in the armature as you encounter a problem that needs to be resolved.

On the stabilizer of the garment, you’ll frequently mark the position right down. The issue generally arises right before the ending stage, supplying you with a design reference point. Leaving the computer running while fixing the issue is n’t always the stylish option, substantially while using multi-head bias digitizing for embroidery.

Needles Are not Acclimated frequently Enough

On artificial embroidery bias, there are no rigid and quick guidelines for changing needles. There are numerous effects to flash back , including the number of hours the system works, the form of material used, and the needle effectiveness. Testing the needles at least formerly a week and removing them when needed, is a healthy routine to establish.

It’s pivotal to replace needles regularly, substantially if the timing is out and the needle is n’t going in pattern with the bobbin case. However, it’ll scrape the bobbin case and detector churrs, fraying and breaking the thread, If a fraudulent needle isn’t replaced. This continuing concern cuts into manufacturing time and gives rise to the problem of cap embroidery.

Thread Pressure

The most notorious blunders in artificial embroidery are thread pressure problems. Regularly cover thread pressure to help implicit cap embroidery problems. else, the thickness department may be overburdened. Acceptable pressure, which causes the aches to be smooth and secure, is frequently a positive suggestion of thickness.

The icon and totem limpidness couldn’t be affected by the embroidery machine still maintaining the correct thread pressure.

Forgetting About Digitizing

The significant error created in marketable embroidery of caps is forgetting to digitally catch a totem or pattern and insure that it fits each particular product. Caps and headdresses are incredibly tricky to embroider on, and train patterns made for flat like T- shirts may produce difficulties when used for embroidery. In a twisted subcaste, compensation attached to the face is distinct from compensation applied to a smooth face. Where needed, a professed embroidery digitizer can use the data collected for pulling payment for rounded shells to be changed. Avoiding these crimes would help sustain a reasonable degree of thickness and reduce cap embroidery problems you have to make.

Incorrect Placement Of A Design

still, you can enlarge the design while stretching a cap, If guests ask for a lower embroidery design placed next to the price. It’s fairly popular to wear trendy caps that give the chance to buy new exaggerated particulars Embroidery digitizing services. Since the client doesn’t realize that it’s a defective idea to embellish designs so low on a cap. The design is doubtful to be approved. However, it may contribute to inaccurate positioning. If a design approach is incorrectly applied.

Before assembling the cap, important of the time, the sewing had been performed on a flat panel operation. An educated needleworker can work with pieces of fabric or other garments that have formerly been prepared. To put an embroidery pattern no lower than half an inch down from either the frontal head or sides of the cap is confined to embroidery positioning. And if you ever manage to capture a needle on the body of the cap. Or the frame, the computer may probably fail.