In the dynamic world of electronics, innovation, and advancement are key drivers of success. As technology continues to evolve at a rapid pace, it is crucial for manufacturers to leverage the expertise of electronic contract manufacturing services to stay competitive. Collaborative manufacturing has emerged as a powerful force behind electronic advancements, enabling manufacturers to tap into specialized resources and expertise. In this blog, we will explore how collaborative manufacturing drives electronic advancements, with a particular focus on the unique approaches employed by Star Engineering, Inc. in the USA.

From electronic contract manufacturing services to cutting-edge tools, we will delve into the components that fuel innovation in this exciting industry.

The Rise of Electronic Contract Manufacturing Services

Electronic contract manufacturing services (ECMS) have become indispensable partners for manufacturers seeking to streamline their production processes and accelerate time to market. These services offer a range of benefits, including access to specialized skills, reduced costs, and increased flexibility. Contract electronics manufacturers in the USA, such as Star Engineering Inc., have established themselves as key players in this field, delivering high-quality solutions to meet the demands of a diverse range of industries.

Collaboration as the Driving Force:

Collaboration lies at the heart of successful electronic manufacturing endeavors. By partnering with ECMS, manufacturers gain access to a vast pool of knowledge and expertise. Through open communication and shared goals, collaborative manufacturing fosters innovation and accelerates the development of cutting-edge electronic solutions. It allows manufacturers to focus on their core competencies while leveraging the specialized capabilities of ECMS, ultimately leading to enhanced product quality and customer satisfaction.

Leveraging Specialized Expertise:

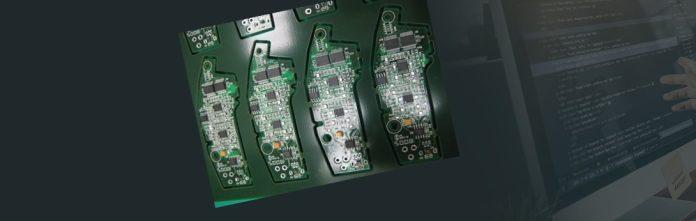

One of the primary advantages of collaborative manufacturing is the ability to tap into the specialized expertise of contract electronics manufacturers. These companies possess in-depth knowledge and experience in areas such as PCB assembly, electromechanical assembly, and surface-mount technology (SMT). By collaborating with ECMS like Star Engineering Inc., manufacturers can harness this expertise to overcome technical challenges, optimize production processes, and ensure the delivery of high-performance electronic products.

Streamlined Production Processes:

Collaboration with ECMS streamlines production processes and reduces time to market. Electronic contract manufacturing companies utilize advanced electronic manufacturing tools to enhance efficiency and productivity. These tools encompass a wide range of technologies, including automated assembly systems, robotics, and state-of-the-art testing equipment. By integrating these tools into the collaborative manufacturing process, manufacturers can achieve faster turnaround times, improved product quality, and increased scalability.

Accelerating Research and Development:

Innovation is the lifeblood of the electronics industry, and collaborative manufacturing plays a significant role in driving research and development efforts. By working closely with ECMS, manufacturers can leverage their research and development capabilities to explore new technologies, refine existing designs, and push the boundaries of what is possible. This collaboration not only enhances product innovation but also enables manufacturers to adapt quickly to market demands, ensuring their competitiveness in the ever-evolving electronic landscape.

Star Engineering, Inc.: Fostering Innovation through Collaboration

Star Engineering Inc. stands out as a trusted partner in collaborative electronic manufacturing. With a focus on innovation, they employ unique approaches to foster collaboration and fuel advancements in the industry. Here’s how Star Engineering Inc. differentiates itself in the collaborative manufacturing process:

- Open Communication Channels: We believe in open communication channels between manufacturers and our team of experts. By fostering a collaborative environment, they encourage continuous feedback, idea exchange, and active participation throughout the manufacturing process. This ensures alignment of goals, efficient problem-solving, and successful project outcomes.

- Design for Manufacturability (DFM) Expertise: We provide valuable DFM expertise to manufacturers, facilitating seamless integration of design and manufacturing. Our team works closely with manufacturers to optimize product designs, ensure manufacturability, reduce production costs, and enhance overall product quality. By considering manufacturing constraints from the early stages, they eliminate potential design issues and streamline the production process.

- Cutting-Edge Manufacturing Tools: We invest in state-of-the-art electronic manufacturing tools to deliver high-quality products efficiently. Our advanced manufacturing facilities are equipped with automated assembly lines, precision testing equipment, and quality control systems. These tools enable efficient production, meticulous testing, and adherence to industry standards, ensuring the delivery of top-notch electronic products.

- Collaborative Project Management: We adopt a collaborative project management approach, providing manufacturers with transparency and control over the manufacturing process. They offer project visibility, regular progress updates, and collaborative decision-making to keep manufacturers informed and engaged throughout the project lifecycle. This collaborative project management approach minimizes risks, maximizes efficiency, and ensures successful project outcomes.

Conclusion

Collaborative manufacturing acts as a driving force behind electronic advancements, propelling innovation and pushing the boundaries of technology. By harnessing the expertise and resources of electronic contract manufacturing services, manufacturers can unlock the full potential of their electronic products. Star Engineering, Inc., with its commitment to collaboration and innovation, stands as a leader in the field, fostering collaboration and fueling advancements through its unique approaches. Partnering with Star Engineering, Inc. ensures access to specialized expertise, streamlined supply chain management, and cutting-edge manufacturing tools, ultimately driving the success of electronic advancements. Contact us to discover how our collaborative manufacturing services can fuel your electronic innovations.