As a writer, I can’t help but get a little giddy anytime a fresh approach to product Pillow Boxes makes its debut on the market. My hands are just too tempting to ignore. A notion occurred to me today as I was taking in the information presented in a video that taught me how to construct a home for cats. “Why don’t you write something that teaches people about packaging?” The concept was not ready to be implemented, and while I struggled with it, I had a sense of submission. Now that we’ve established that, allow me to provide you with a detailed guide on how to make pillow boxes!

To begin, it is a handbook that goes through each stage in sequential order. It is not a simple task to create a box’s design. It is common knowledge that consumers form opinions regarding the quality of a product based on how it is packaged. As a result, a Custom Pillow Packaging box needs to be specially developed, printed in a professional setting, and used to encase the goods in a precise manner.

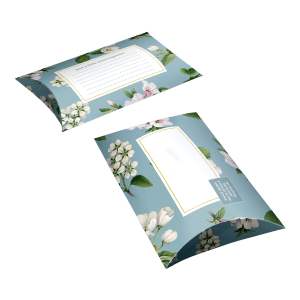

When it comes to the style of packaging for pillows, I have to say that these boxes have surpassed all of the other styles available. It’s funny how some individuals get pillow packing boxes mixed up with pillow packaging while they’re looking for pillow packaging. ha.ha. These containers are referred to as “pillow boxes” due to the fact that their inwardly curved sides give them the appearance of pillows.

In order to begin building pillow boxes, the first thing you need to do is determine the type of item that will be contained within them.

1. Examine The Item In Great Detail

Examining the product that will be used is the first step in the process of producing pillow boxes. custom pillow packaging for pillows that are made to order has its own distinctive flair. There are situations when a product cannot be used in conjunction with such packaging. Due to the fragile and perishable nature of a two-point cake, for instance, it cannot be placed inside of it. In a similar vein, pillow packaging is not the optimal choice for transporting liquids like water bottles and beverages.

Before opting to move forward with pillow-style packaging, it is therefore absolutely necessary to examine the product in great detail. The bespoke pillow boxes are the best option for you to go with if you are a producer and/or supplier of any of the product categories that are listed below, however.

- Small cosmetics

- Jewelry

- Soaps and detergents

- Products used for makeup

- Hair extensions

- Items sold in smaller retail outlets

2. Choice Of Construction Materials

The selection of the material constitutes the second step. The eco-friendliness of custom boxes is one of the reasons for their widespread popularity. The eco-friendliness of custom boxes is largely attributable to the material in question. The material, in addition to being kind to the environment, is critical to the production of high-quality printing, the formation of the box, and the aesthetic appeal of the product as a whole. There are two different types of materials that work exceptionally well for building pillow boxes.

Kraft The Kraft variety of paper is a sturdy product. Because of its natural brown tone, there is only a little amount of room for color printing. However, this does not imply that the surface of Kraft cannot accommodate a significant amount of printing. This material is suitable for use in both relatively small and relatively big goods. Pillow Kraft Boxes provide a safe and secure container for delicate items such as jewelry, cosmetics, and small supermarket items.

Cardboard

The cardboard has a finish that is completely smooth. On it, you can print pretty about any design, artwork, or style you can think of. Cardboard is an excellent medium for displaying the fundamental characteristics of common CMYK colors. It is a challenge.

The capacity of cardboard to resist both tearing and tensile force is astounding. since a result, cardboard is the most suitable material for fabricating individualized pillow boxes, since it allows for the most printing, laminating, and design options.

3. Customized And Unique Layouts

It’s a lot of fun to create your own pillow box. Because there are so many choices, it feels like you’re on a roller coaster that never stops. In addition, the style is not the only aspect of the design that requires a significant amount of time. In the end, the true magic lies in the individualized design work that is done.

custom pillow packaging that is designed in the form of a pillow is not difficult to design. The design features curved bending on both the left and right sides. The tuck ends serve as access points for opening the curves. When the curve is rotated in the opposite direction, a notch for the thumb appears; by pushing on this notch, the lid of the box can be removed. However, the design of this particular pillow box is the simplest of them all. One can only make educated guesses on the complexity of this design.

Boxes For Pillows That Have Handles

When it comes to design, the Pillow Boxes with Handles have become the most popular choice among American consumers. The portability provided by these boxes is second to none. Handles are similarly composed of cardboard and Kraft and are attached to the top of the package. If a product needs to be hand carried for a significant distance, you might choose this box as the appropriate packaging for it.

Boxes For Pillows That Have Windows

The window-mounted kind of pillow packaging is yet another prevalent form of pillow packaging. In such boxes, you have the option of installing a see-through PVC transparent window at the front, which enables buyers to better visualize the goods they are purchasing.

Pillow boxes designed in the appearance of windows have astonishingly dominated the extremely competitive industry for packaging. Because the window on the front of these boxes allows you to see the contents without having to open the packing, they eliminate the need to do so.

Boxes For Gift Pillows Made To Order

Gift The category of pillow boxes is one that is not very common. There are many different ways in which a present pillow box can be personalized. You could tie ribbon around these boxes and use the ribbon to carry the merchandise rather than a traditional handle if you wanted to. Within the gift category, you also have the option of having the folding pillow-style boxes.

4. The Printing Phase Of The Process

The printing stage starts after the material is chosen to be printed on. When the packing style is as elegant as pillow boxes, the printing is ultimately what makes all of the difference in the world.

People really like having custom printing on the box of their pillows. It sets their products apart from those of their competitors. Therefore, what are the available choices for individualized printing? It’s true that there are a lot of different technologies that can help improve print quality. Check out the list that’s provided below.

- Offset Printing

- Digital Printing

- Printing Methods: Flexography and Screen Printing

- Printing Done With Holograms

Both digital and offset printing technologies can be utilized to create visually appealing prints for pillow boxes. In spite of the fact that both methods are distinctive in their own right, digital printing is favoured since it provides a greater variety of coloring options. With these printing options, you can print any color, artwork, or design you can think of, and most importantly, the logo for your company.

5. Concluding With Extravagance Add-Ons

We are quite close to finishing everything now. The printing process is complete. We were quite specific in our selection of the material and design that we wanted to print. Now, as a last step, why not cap things off by adding some premium add-ons?

Add-ons are any items that are added to a box in order to make it look more attractive or decorative. They improve the overall appearance of the surface of the packaging. Add-ons are frequently utilized by businesses on the product packaging in order to bring attention to certain information, designs, or logos.

The gloss and matte lamination, pillow boxes with inserts, gold and holographic foiling, and foiling with a holographic pattern are the most notable of these various add-ons. Lamination is something that people almost universally request to have done initially, even if they also use add-ons, glitters, and the like.

I really hope that this brief tutorial on how to build pillow boxes was enjoyable for you to read. I trust that the process of manufacturing pillow boxes from the ground up is now crystal evident to you. I’ll get back to you as soon as I think of something interesting to write about. I’ll see you later, bye for now.