We rely on various tools, products, appliances, and machines for our societies to run smoothly. All these need to be created or manufactured by us, and Computer Numerical Control machining (CNC machining) is one of the best methods we have at our disposal.

While plenty of CNC service providers are out there, you need to be careful when selecting to ensure you get the best results possible. To help you along, here’s a quick look at the factors you should consider when picking a CNC machining company.

Let’s jump right in.

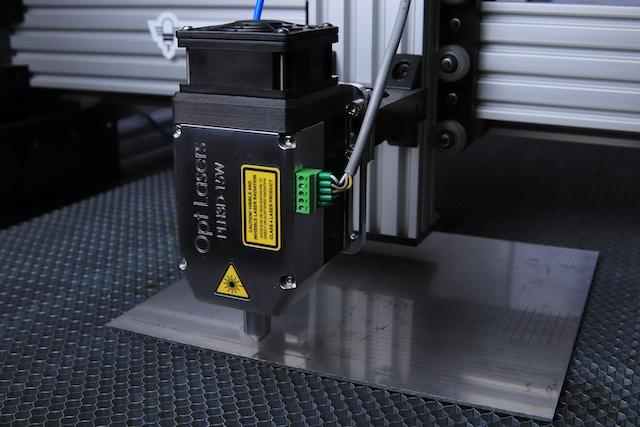

Technological Capacity

To deliver the best results possible, the company you select should have the latest machinery at its disposal. The advantage of state-of-the-art technology is that the parts and products manufactured will be more precise and will be produced at a faster rate.

Before placing your order, confirm that the company in question has the equipment necessary to deliver your order according to your specifications.

Lead Times and Costs

While it makes financial sense to seek out the best prices possible, you should never compromise on the quality of your products in the pursuit of saving money. You will likely lose money in the long run. Also, find out how long you should expect to receive your order.

Quick turnaround times will give you the leeway and flexibility to minimize production delays and meet tight deadlines.

Certifications and Quality Assurance

In the CNC machining industry, any tiny flaw may result in untold damage if not detected. Any CNC company worth its salt will have a robust quality assurance protocol in place. Seek out industry-specific quality certifications, such as AS9100 or ISO 9001. Such certifications serve as evidence that the company in question maintains high standards.

Customization Capabilities

Not all machining companies have the equipment, skills, and capacity to produce customized parts. If your project requires custom parts, you’ll need a provider that can work with unique materials and create unique parts. A custom CNC machining company will be able to turn your dreams into a reality.

Expertise and Experience

A CNC machining company’s experience and expertise are, perhaps, the two most critical factors to consider when selecting a company to supply you with the parts you need. A competent company should have a proven track record of high quality, consistency, cost-effectiveness, and trust.

Searching for customer reviews and testimonials online is a great way to assess a company’s competence. You can evaluate their capabilities by viewing their portfolio. A company with experience in producing parts and products similar to what you require will be a good choice for you.

Final Thoughts

CNC machining has a broad range of applications in the building, aerospace, medical, automotive, and other industries. To save time and money in the long run while ensuring you get the best possible outcome, you should always consider the elements outlined in this article.

Beska Mold is a highly respected and experienced CNC machining company with decades of experience supplying precise, complex parts to clients worldwide. For world-class machining at cost-effective rates, make Beska Mold your first call. You won’t regret it!

For more blogs click here.