In the ever-evolving realm of construction, materials, and techniques continuously undergo innovations to enhance structural integrity, cost-efficiency, and sustainability. One such innovation that has gained prominence in recent years is light gauge steel framing. This construction method, known for its versatility and strength, is transforming the industry and revolutionizing construction methods. In this article, we will delve into light gauge steel frame, exploring their benefits, applications, and the role of steel structure manufacturer in India.

Understanding Light Gauge Steel Frames

Light gauge steel frames are engineered structural components made from thin sheets of high-strength steel. These sheets typically protect against corrosion, making them durable and long-lasting. The lightweight qualities of these steel frames set them apart from traditional construction materials like wood or concrete.

Benefits of Light Gauge Steel Frames

1. Strength and Durability: Light gauge steel frames offer exceptional strength and durability, providing buildings with a robust structural framework.

2. Lightweight: The lightweight nature of steel frames simplifies transportation and handling on construction sites. It can lead to reduced labour and material costs.

3. Design Flexibility: Steel frames are highly adaptable, allowing for intricate architectural designs. They can be easily customized to meet specific project requirements, offering architects and builders greater design flexibility.

4. Sustainability: Steel is a recyclable material, and its use in construction reduces the need for virgin resources. Additionally, the long lifespan of steel structures minimizes the environmental impact associated with frequent maintenance and replacement.

Applications of Light Gauge Steel Frames

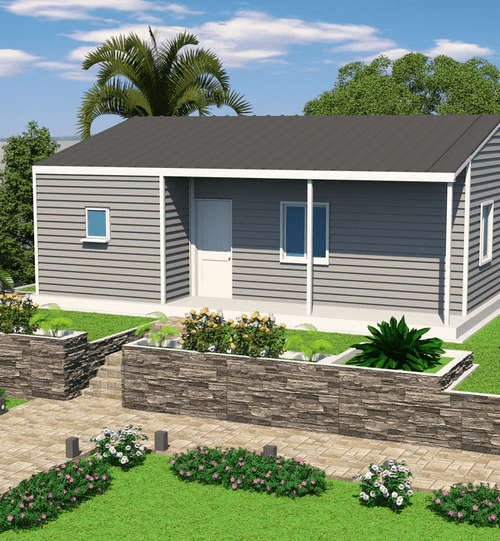

1. Residential Construction: Light gauge steel frames are increasingly popular in residential construction, and people use them in framing houses, apartments, and condominiums.

2. Industrial Facilities: Steel frame buildings are often used for industrial facilities including manufacturing plants and factories. They can accommodate the specialized equipment and machinery required in industrial settings.

3. Agricultural Structures: Steel frame buildings are also employed in the construction of agricultural facilities, including barns, silos, and steel farm buildings. They offer protection for livestock, machinery, and crops.

Role of Steel Structure Manufacturers in India

India has witnessed a significant increase in the use of light gauge steel frames in construction. This surge can be attributed, in part, to the presence of reputable steel structure manufacturers who produce high-quality steel framing components. These manufacturers promote the adoption of steel framing in the construction industry and here’s how:

1. Quality Production: Steel structure manufacturer in India adhere to stringent quality standards to ensure that their products meet or exceed industry requirements. This commitment to quality instills confidence in builders and developers.

2. Customization: Manufacturers offer a range of steel framing components tailored to different construction needs. They can customize components to fit specific project requirements, allowing for greater flexibility in design and construction.

3. Technical Support: Reputable manufacturers provide technical support and guidance to architects, engineers, and builders. This assistance ensures that steel framing systems are designed and installed correctly, optimizing their performance.

4. Cost Efficiency: The efficiency of manufacturing processes and economies of scale enable steel structure manufacturers to offer cost-effective solutions. This affordability makes steel framing an attractive option for various construction projects.

5. Sustainability: Many steel structure manufacturers in India prioritize sustainability by using eco-friendly production processes and promoting the recyclability of steel materials. It aligns with global efforts to reduce the environmental impact of construction.

Advancements in Light Gauge Steel Technology

The continued development of light gauge steel technology is another factor for its widespread adoption in India’s construction landscape. Innovations in materials and manufacturing processes have further improved the already impressive properties of light gauge steel frames.

1. High-Strength Steel Alloys: The advanced high-strength steel alloys have led to even lighter yet stronger frames. It translates to reduced material requirements while maintaining structural integrity, resulting in cost savings and sustainability benefits.

2. Improved Corrosion Resistance: Manufacturers are now using superior corrosion-resistant coatings, such as zinc-aluminium coatings, which enhance the longevity of light gauge steel frames.

3. Modular Construction: Light gauge steel frames are well-suited for modular construction methods. As India faces the rapid need for urbanization and affordable housing solutions, modular construction with steel frames offers a quick and efficient way to meet these demands.

Conclusion

Light gauge steel frames have emerged as a modern marvel in the construction industry, offering numerous advantages such as strength, durability, design flexibility, and sustainability. Their applications span across residential, commercial, industrial, and agricultural sectors, making them a versatile choice for builders and developers. The role of steel structure manufacturer India, like TSSC Group is pivotal in driving the adoption of steel framing.