When you pour a bowl of your favorite breakfast cereal in the morning, have you ever wondered about the journey it took to get there? That crispy, flavorful, and nutritious cereal starts its life in a breakfast cereal plant, where grains are transformed into the beloved breakfast staple. In this article, we’ll take you behind the scenes to explore the inner workings of a breakfast cereal plant, from the raw ingredients to the finished product.

The Breakfast Cereal Production Process

- Ingredient Selection and Preparation

The first step in cereal production is the careful selection of ingredients. While the exact recipe may vary from one cereal to another, the core components typically include grains such as wheat, oats, corn, or rice. These grains are cleaned, sorted, and sometimes roasted to enhance their flavor.

- Milling and Mixing

Once the grains are prepared, they are sent to a milling machine, where they are ground into a coarse flour known as “grits.” Different types of grains are mixed together in precise ratios to create the desired flavor and texture of the cereal. Additional ingredients, such as sugar, salt, and vitamins, are also mixed in at this stage.

- Cooking and Shaping

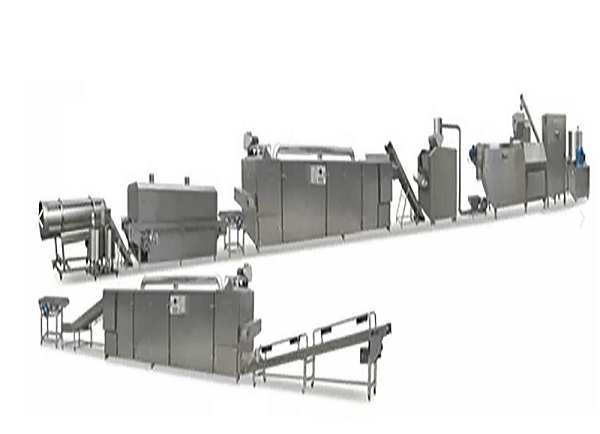

The mixture is then cooked, usually through a process called “extrusion.” In this process, the grits are subjected to high temperature and pressure, causing them to puff and expand. The cooked mixture is then shaped into the familiar cereal pieces, which can range from flakes and loops to puffs and squares.

- Drying

The shaped cereal pieces are dried to remove moisture and ensure long shelf life. This is typically done in a large drying oven, where hot air circulates around the cereal until it reaches the desired moisture content.

- Flavoring and Coating

Cereals often receive an additional layer of flavoring or coating to enhance their taste and texture. This can include sugar, honey, cocoa, or fruit flavorings. The coating is carefully applied to ensure even distribution.

- Packaging

After all the processing steps are complete, the cereal is ready to be packaged. It is weighed, sealed in airtight bags or boxes, and labeled with nutritional information and branding. Packaging is a critical step in preserving the freshness and quality of the cereal.

Modern Technologies in Breakfast Cereal Plants

Automation

Breakfast cereal production has seen significant advancements in automation. Automated systems handle tasks such as ingredient measurement, mixing, shaping, and packaging, reducing the need for manual labor and ensuring consistency in quality.

Quality Control

Breakfast cereal plant employ sophisticated quality control measures to ensure the final product meets stringent standards. Automated sensors and cameras are used to detect irregularities in shape, size, and color, allowing for immediate adjustments in the production process.

Energy Efficiency

To reduce their environmental footprint, many cereal plants have adopted energy-efficient technologies. This includes using energy-efficient ovens, recycling heat, and optimizing energy consumption throughout the production process.

Varieties of Breakfast Cereals

Flakes

Flakes are one of the most common types of breakfast cereal. They are typically made from grains like corn or wheat and are known for their crispiness and wide range of flavors.

Puffs

Puffed cereals are created by subjecting grains to extreme heat and pressure. When the pressure is released, the grains expand, resulting in light, airy, and crunchy cereals.

Granola

Granola cereals are made from whole grains, nuts, seeds, and sweeteners like honey. They are often baked until they are crisp and clustered together, creating a hearty and nutritious option.

Oatmeal

Oatmeal cereals consist of rolled or instant oats that are typically cooked with hot water or milk. They are known for their creamy texture and are often flavored with fruits, nuts, or sweeteners.

Breakfast Cereal Plant Sustainability

Modern breakfast cereal plants are increasingly focused on sustainability practices. This includes sourcing ingredients responsibly, reducing water and energy consumption, and minimizing waste. Many plants also invest in renewable energy sources to power their operations, contributing to a greener and more sustainable breakfast cereal industry.

Conclusion

The breakfast cereal you enjoy each morning is the result of a meticulous process that begins in a breakfast cereal plant. From ingredient selection and preparation to shaping, flavoring, and packaging, each step plays a crucial role in delivering the crispy, flavorful, and nutritious cereals that have become a beloved part of breakfast traditions worldwide. With advancements in technology and a growing commitment to sustainability, breakfast cereal plants continue to evolve, ensuring that your morning bowl of cereal is both delicious and environmentally responsible.