Machine embroidery has revolutionized the world of textile artistry. Whether you’re an enthusiast or a professional, you understand that every stitch counts when it comes to creating exquisite designs. Thread selection is a critical aspect of machine embroidery, and one factor that often confounds embroiderers is thread weight.

In this comprehensive guide, we will delve deep into the world of thread weights for machine embroidery. We will explore what thread weight means, how it impacts your embroidery projects, and which thread weights are ideal for different situations. So, if you’re ready to unravel the mystery of thread weights, let’s thread the needle and get started!

Understanding Thread Weight

Before we dive into the specifics of thread weights for machine embroidery, let’s clarify what thread weight actually means. Thread weight refers to the thickness or diameter of the thread, and it is usually denoted by a number. The higher the thread weight number, the finer and thinner the thread. Conversely, lower thread weight numbers represent thicker and heavier threads.

Now that we have the basics covered, let’s explore the world of thread weights and machine embroidery.

The Impact of Thread Weight on Machine Embroidery

The choice of thread weight can significantly influence the outcome of your embroidery projects. Here’s how it can impact your work:

1. Design Detail and Complexity

- Keywords: machine embroidery designs, embroidery digitizing company

The thread weight you choose can make or break the level of detail and complexity you can achieve in your designs. If you’re working on intricate and delicate designs, opting for a finer thread, like 60 wt or 50 wt, is advisable. These threads allow you to capture small details with precision, making them ideal for embroidery digitizing company projects that require intricate artwork to be translated into thread.

Conversely, if you’re aiming for bold and eye-catching designs, thicker threads like 30 wt or 12 wt can help you achieve a more pronounced and textured look. These heavier threads create a bolder appearance that’s perfect for making designs stand out.

2. Fabric Compatibility

- Keywords: machine embroidery designs, zdigitizing

Different fabrics have different requirements when it comes to thread weight. Lightweight fabrics, such as chiffon or organza, may be better suited for finer thread weights like 60 wt. These threads won’t overpower the delicate fabric and will ensure that the embroidery remains subtle and graceful.

On the other hand, when working with heavy fabrics like denim or canvas, thicker threads (30 wt or 12 wt) may be necessary to penetrate the fabric effectively and create a strong visual impact. This is especially important for machine embroidery designs that need to be visible on sturdy materials.

3. Texture and Dimension

- Keywords: vector art services, zdigitizing

If you’re aiming to add texture and dimension to your embroidery, thread weight plays a pivotal role. Heavier threads, such as 30 wt or 12 wt, create a pronounced texture and give your designs a three-dimensional effect. This is particularly useful when you want your embroidery to pop off the fabric.

For vector art services and zdigitizing projects where you want to mimic the appearance of textures, like fur or wood grain, opting for heavier threads can help achieve a more realistic and tactile result.

4. Durability and Colorfastness

- Keywords: embroidery digitizing company

The choice of thread weight can also impact the durability and colorfastness of your embroidery. Polyester threads, which are known for their colorfastness and resistance to fading, are often available in a variety of thread weights. If you’re working on projects that will be frequently washed or exposed to the elements, using a thread weight that’s suitable for the fabric and design is crucial.

An embroidery digitizing company can help you select the right thread weight based on the specific requirements of your project, ensuring that your embroidery remains vibrant and intact over time.

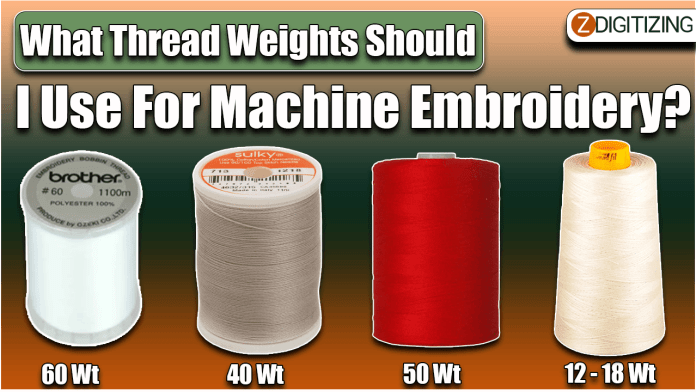

Common Thread Weights for Machine Embroidery

Now that we understand how thread weight influences embroidery projects, let’s explore some common thread weights and their ideal uses:

1. 40 wt

- Keywords: machine embroidery designs

40 wt threads are the workhorses of machine embroidery. They are versatile and suitable for a wide range of embroidery designs and fabrics. They provide good coverage and are ideal for both intricate and bold designs. These threads are often used in machine embroidery designs that require a balance between detail and impact.

2. 30 wt

- Keywords: embroidery digitizing company

30 wt threads are slightly thicker and are excellent for designs that you want to stand out prominently. They create a bolder and more textured appearance, making them suitable for decorative elements or lettering in embroidery. When you work with an embroidery digitizing company, they can guide you on when to use 30 wt threads for specific design elements.

3. 60 wt

- Keywords: vector art services

60 wt threads are on the thinner side and are ideal for fine details and delicate designs. They are often used for small lettering and intricate embroidery work, especially on lightweight fabrics. When utilizing vector art services to convert your designs, consider using 60 wt threads for the finest details.

4. 50 wt

50 wt threads strike a balance between coverage and detail. They are commonly used for general-purpose embroidery on a variety of fabrics, making them a popular choice among embroiderers. When versatility is key, 50 wt threads can often be the go-to choice for machine embroidery.

5. 12 wt

- Keywords: zdigitizing

12 wt threads are heavyweight threads that add a pronounced texture to your embroidery. They are often used for creating a 3D effect or a bold, raised appearance in designs. When working on zdigitizing projects that require a tactile and striking finish, 12 wt threads can be your best bet.

Factors to Consider When Choosing Thread Weight

When it comes to selecting the right thread weight for your machine embroidery project, several factors should be taken into consideration:

- Fabric Type: The type of fabric you’re working with plays a crucial role. Different fabrics may require different thread weights to ensure proper coverage and stability. For example, lightweight fabrics may work well with thinner threads, while heavier fabrics may benefit from thicker ones.

- Design Complexity: The complexity of your design determines the level of detail you need to achieve. Fine threads are perfect for intricate designs, while thicker threads are better suited for bold and large designs.

- Personal Preference: Your personal style and the effect you want to achieve in your embroidery are important. Experimenting with different thread weights can lead to unique and creative outcomes.

- Machine Capability: Ensure that your embroidery machine can handle the selected thread weight. Consult your machine’s manual or the manufacturer’s recommendations for guidance.

Conclusion

Thread weight is a critical aspect of machine embroidery that can significantly impact the outcome of your projects. Understanding how different thread weights affect your designs, fabrics, and textures is essential for achieving the desired results. Whether you’re working on intricate machine embroidery designs, collaborating with an embroidery digitizing company, or exploring the world of vector art services and zdigitizing, choosing the right thread weight is the key to success.