Embroidery has come a long way, transforming simple fabrics into intricate masterpieces. As technology evolves, the options for embroidery machines have expanded to include single-head and multi-head machines. Each option has its unique advantages and challenges. In this article, we’ll delve into the world of embroidery digitizing services, focusing on the problems associated with cap embroidery and comparing single-head and multi-head machines. So, let’s thread our way through the intricate details!

Introduction

Embroidery digitizing is an intricate art that transforms digital designs into embroidered masterpieces. Whether it’s a custom logo on a cap or an intricate pattern on a garment, embroidery digitizing services play a crucial role in bringing these designs to life. However, when it comes to cap embroidery, there are specific challenges that both single-head and multi-head machines must contend with.

Understanding Embroidery Digitizing Services

Embroidery digitizing services are the bridge between digital designs and embroidered creations. Skilled technicians meticulously convert complex designs into machine-readable formats. These digitized files guide embroidery machines, dictating the stitch patterns and color changes necessary to recreate the design accurately.

The Art of Cap Embroidery

Cap embroidery presents a unique canvas for creativity. However, the curved surface and limited space of a cap can pose challenges. Achieving precise alignment and maintaining stitch quality require specialized techniques and machinery.

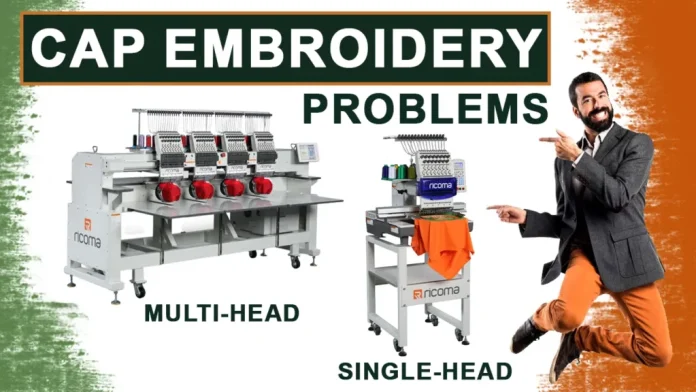

Single-Head Embroidery Machines: Pros and Cons

Single-head embroidery machines offer versatility and are excellent for smaller projects. They allow for quick design changes and are well-suited for intricate designs. However, their single-needle setup can be time-consuming for larger orders.

Multi-Head Embroidery Machines: Advantages and Limitations

Multi-head machines, with multiple needles and heads operating simultaneously, are ideal for large-scale production. They ensure faster completion of bulk orders but may be less flexible for smaller runs or frequent design changes.

Common Problems in Cap Embroidery

1. Thread Tension Issues

Improper thread tension can lead to uneven and messy embroidery. Finding the right balance is crucial for clean and professional results.

2. Alignment Problems

Misalignment can result in skewed designs or off-center embroidery. This is particularly challenging on curved surfaces like caps.

3. Puckering and Buckling

Excessive tension or inadequate stabilization can cause fabric puckering or design distortion, marring the overall appearance.

4. Design Distortion

Curved surfaces can cause design distortion if not digitized and hooped correctly, resulting in stretched or squished designs.

5. Thread Breakage

High-speed embroidery combined with cap’s curves can lead to thread breakage. This disrupts the embroidery process and requires frequent intervention.

Addressing Cap Embroidery Challenges

To conquer the challenges of cap embroidery, consider the following:

1. Choosing the Right Design

Opt for designs tailored to caps, avoiding overly complex or intricate patterns that may not translate well.

2. Quality Digitizing Services

Invest in professional digitizing services that understand the nuances of cap embroidery.

3. Hooping Techniques

Master hooping techniques specific to caps to ensure proper tension and alignment.

4. Regular Maintenance

Keep your embroidery machines well-maintained to prevent unexpected issues during production.

Single-Head vs. Multi-Head: Which is Better for Cap Embroidery?

The choice between single-head and multi-head machines depends on the scale and nature of your embroidery projects. Single-head machines are versatile but time-consuming for larger runs, while multi-head machines excel in mass production but may lack flexibility.

Expert Tips for Successful Cap Embroidery

- Use quality threads to minimize thread breakage.

- Test new designs on scrap fabric before committing to the final product.

- Prioritize proper hooping techniques to ensure consistent results.

Conclusion

Embroidering caps is an intricate craft that demands attention to detail and an understanding of the challenges involved. Whether you opt for the versatility of a single-head machine or the efficiency of a multi-head setup, addressing common cap embroidery problems is essential. By investing in quality digitizing services, mastering hooping techniques, and staying attuned to machine maintenance, you can produce stunning embroidered caps that truly stand out.

FAQs

- What is embroidery digitizing? Embroidery digitizing service is the process of converting intricate designs into digital files that embroidery machines can interpret and replicate.

- Which machine is better for cap embroidery, single-head, or multi-head? The choice depends on your production scale. Single-head machines are versatile, while multi-head machines are more efficient for large-scale orders.

- How can I prevent thread breakage during cap embroidery? Using high-quality threads, ensuring proper tension, and regular machine maintenance can help prevent thread breakage.

- What is the significance of proper hooping techniques? Proper hooping ensures that the fabric remains taut and aligned, resulting in accurate and clean embroidery.