In the world of precision manufacturing, achieving the perfect balance between form and function is paramount. Industries across the spectrum rely on cutting-edge technologies and skilled craftsmanship to produce components that meet exacting standards. One crucial aspect of this process is grinding – a precision machining technique that transforms raw materials into finely finished products. When it comes to high-quality grinding solutions, one name stands out: Midway Grinding Inc. With their expertise in OD grinding and cylindrical grinding services, Midway Grinding Inc. has become a trusted partner for industries seeking perfection in their components.

Introduction to Midway Grinding Inc

Midway Grinding Inc. is more than just a company; it’s a testament to the synergy between innovation and tradition. Specializing in OD (Outer Diameter) grinding and cylindrical grinding services, Midway Grinding Inc. has been a cornerstone of precision manufacturing for years. Their commitment to providing top-notch solutions has earned them a reputation that extends far beyond their headquarters.

The Art of Precision Grinding

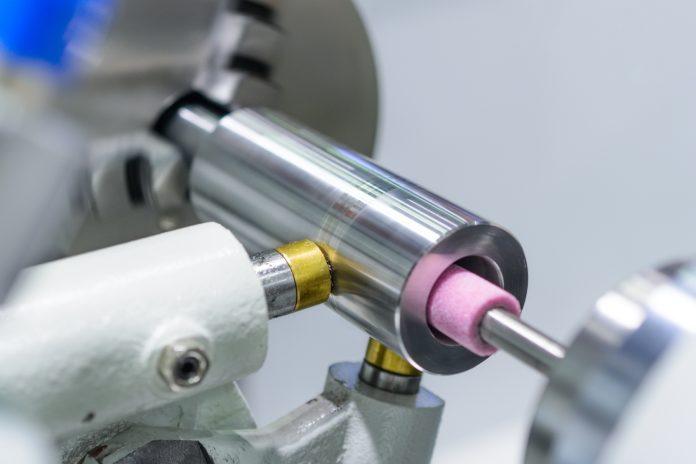

Precision grinding is a meticulous process that involves removing material from a workpiece to achieve the desired shape and finish. This technique is a staple in industries where even the slightest deviation can lead to performance issues or catastrophic failures. Precision grinding is the backbone of many manufacturing processes, from aerospace to medical devices.

Industries Served by Midway Grinding Inc

- Aerospace and Aviation: The aerospace industry demands components that can withstand extreme conditions while maintaining unparalleled precision. Midway Grinding Inc. delivers solutions that meet aerospace’s rigorous requirements from turbine blades to landing gear components.

- Automotive Manufacturing: The automotive sector requires parts that ensure safety, efficiency, and durability. Precision grinding is essential in creating components like engine crankshafts, camshafts, and transmission gears. Midway Grinding Inc.’s expertise ensures that these components perform flawlessly.

- Medical Equipment: Medical devices are often intricate and delicate, requiring precise manufacturing processes. Midway Grinding Inc.’s meticulous approach to cylindrical grinding is ideal for creating medical components like surgical tools, implants, and diagnostic equipment.

- Energy and Power Generation: Reliability is paramount in industries such as energy and power generation. Precision grinding plays a pivotal role in producing components for turbines, generators, and other critical equipment. Midway Grinding Inc. contributes to the seamless functioning of these industries.

- Industrial Tooling: Industrial tools must exhibit durability and precision to withstand the demands of heavy-duty applications. Midway Grinding Inc.’s OD grinding services are instrumental in crafting tooling components that deliver exceptional performance.

- Defense and Military: The defense sector relies on components that guarantee national security. Midway Grinding Inc.’s expertise in grinding contributes to the production of accurate and reliable military equipment.

Why Choose Midway Grinding Inc?

- Unparalleled Expertise: With years of experience under their belt, Midway Grinding Inc. boasts a team of skilled professionals who understand the nuances of precision grinding. Their mastery over both OD and cylindrical grinding techniques ensures that clients receive components of the highest quality.

- Cutting-edge Technology: Precision grinding is as much about technology as it is about craftsmanship. Midway Grinding Inc. combines the best of both worlds by incorporating advanced CNC (Computer Numerical Control) grinding technology. This allows for consistent, repeatable, and high-precision results.

- Commitment to Quality: Quality control is non-negotiable in precision manufacturing. Midway Grinding Inc. adheres to stringent quality control measures to ensure that each component leaving its facility meets or exceeds industry standards.

- Custom Solutions: One size does not fit all in precision manufacturing. Midway Grinding Inc. understands this, offering custom grinding solutions tailored to each client’s specific requirements. This flexibility sets them apart from the competition.

- Reliable Turnaround: In today’s fast-paced industries, time is of the essence. Midway Grinding Inc. takes pride in its efficient turnaround times, helping clients meet tight production schedules without compromising on quality.

Conclusion

Precision grinding is the backbone of modern manufacturing, and Midway Grinding Inc. stands at the forefront of this essential practice. Their expertise in OD grinding and cylindrical grinding services spans diverse industries, ensuring that the aerospace, automotive, medical, energy, industrial, and defense sectors benefit from their commitment to excellence. With a fusion of skill, technology, and dedication to quality, Midway Grinding Inc. continues to be the trusted partner for those who refuse to settle for anything less than perfection. In an era where precision reigns supreme, Midway Grinding Inc. is a beacon of reliability and innovation.