Introduction

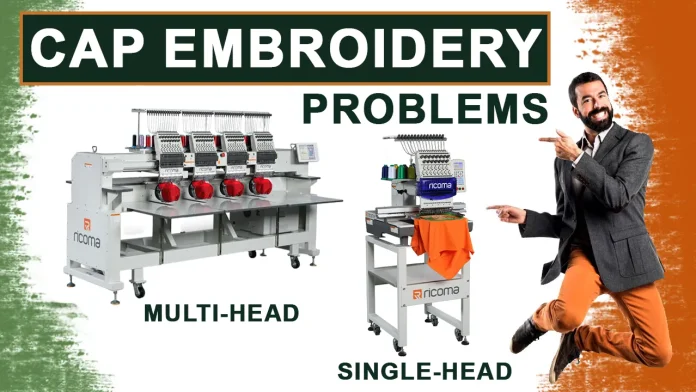

Embroidery is an intricate and beautiful art form that has been around for centuries. Today, with the advent of advanced technology, embroidery machines have become an essential tool for creating stunning designs on various fabrics, including caps. The cap embroidery process involves the use of single-head and multi-head machines, each offering unique benefits and challenges. In this blog, we will explore the common problems faced in cap embroidery and how they differ between single-head and multi-head machines. Additionally, we’ll touch upon the significance of free embroidery designs and the role of zdigitizing in ensuring high-quality results.

Part 1: Cap Embroidery Problems

- Thread Breakage: Thread breakage is one of the most common issues faced during cap embroidery. It can occur due to various factors, such as improper thread tension, poor quality thread, worn-out needles, or even design complexity. Both single-head and multi-head machines can experience thread breakage, but the impact can vary based on the machine’s construction and tensioning mechanisms.

- Puckering: Puckering refers to the wrinkling or gathering of the fabric around the embroidered area, leading to an untidy and unprofessional appearance. Puckering can result from inadequate hooping techniques or improper stabilizer selection. While single-head machines might encounter puckering due to operator errors, multi-head machines could face this issue if all heads are not adequately calibrated and synchronized.

- Design Distortion: Design distortion occurs when the embroidered design appears stretched or compressed, deviating from its original dimensions. This problem can arise when the design is not digitized properly or when it is resized beyond its recommended limits. Both types of machines can be affected by design distortion if the digitizing process is not accurate.

- Bird Nesting: Bird nesting refers to the tangling of thread beneath the fabric during embroidery. This can happen due to several reasons, such as improper thread tension, insufficient lubrication, or a damaged bobbin case. In multi-head machines, bird nesting might affect multiple designs simultaneously, causing more significant production delays compared to single-head machines.

Part 2: Single-Head Machines

Single-head embroidery machines are an excellent choice for small businesses, startups, or hobbyists. They are more affordable, take up less space, and are easier to operate and maintain. However, they do come with their own set of challenges when it comes to cap embroidery:

- Slower Production: Since single-head machines can only work on one design at a time, they have lower production rates compared to multi-head machines. This can be a limiting factor for businesses that require high volumes of embroidered caps.

- Increased Labor Demand: With a single-head machine, the production process relies heavily on manual labor, including hooping and changing caps between designs. This can be time-consuming and physically demanding for the operator.

- Limited Scalability: As your business grows, the demand for embroidered caps might increase. Scaling up production with single-head machines can be challenging, leading to potential delays in fulfilling orders.

Part 3: Multi-Head Machines

Multi-head machines, on the other hand, are designed to handle higher volumes and offer greater efficiency. They have multiple sewing heads that can work simultaneously, enabling faster production rates. However, they also come with their own unique challenges:

- Initial Investment: Multi-head machines are considerably more expensive than single-head machines. This initial investment might be a barrier for small businesses or startups with budget constraints.

- Space Requirement: Multi-head machines are larger and require more space in your embroidery workspace. For businesses with limited room, accommodating a multi-head machine might be challenging.

- Maintenance Complexity: With more moving parts and sewing heads, multi-head machines can be more complex to maintain. Regular maintenance and calibration are crucial to ensuring consistent quality.

Part 4: Free Embroidery Designs and zDigitizing

To enhance your cap embroidery projects and minimize problems, leveraging free embroidery designs can be highly beneficial. Many online platforms offer a vast array of free embroidery designs that cater to various themes, styles, and industries. Utilizing these designs not only saves time but also ensures that you have access to professionally created designs.

However, the success of any embroidery project heavily depends on the digitizing process. zDigitizing plays a crucial role in converting the artwork into a digital embroidery file that can be read and stitched by the machine. A well-digitized design ensures that the embroidery process runs smoothly, reducing the likelihood of thread breaks, distortions, and other issues. Investing in professional zDigitizing services can significantly impact the final output, regardless of whether you are using a single-head or multi-head machine.

Conclusion

In conclusion, cap embroidery can be a rewarding venture, but it comes with its own set of challenges. Understanding the differences between single-head and multi-head machines helps you make an informed decision based on your business requirements. Addressing common problems such as thread breakage, puckering, and design distortion is crucial for achieving high-quality embroidered caps. Additionally, the availability of free embroidery designs and the significance of professional zDigitizing services contribute significantly to the success of your embroidery projects. With the right equipment, techniques, and designs, cap embroidery can become a flourishing aspect of your business or a fulfilling hobby.